Description

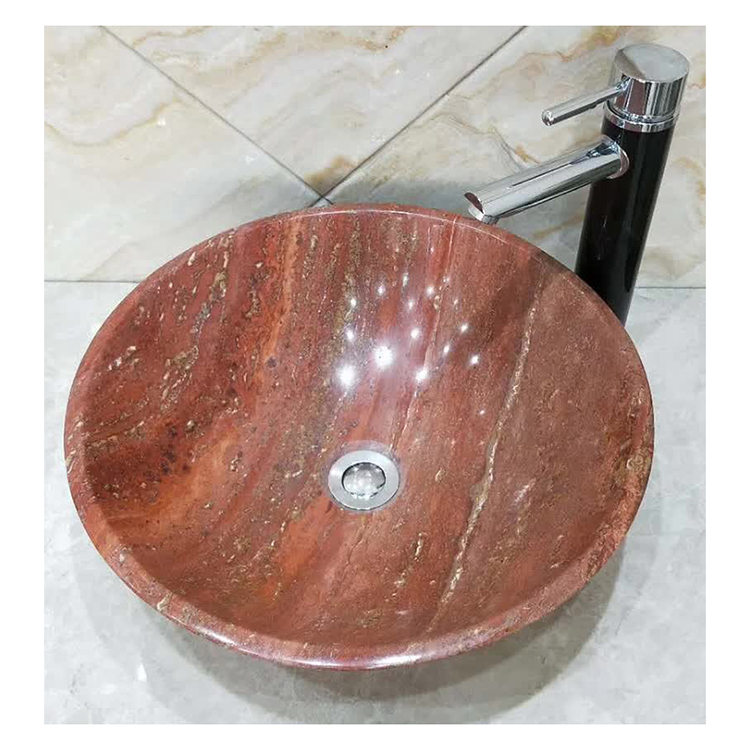

| Product Name | Factory price natural stone bathroom red travertine wash basin and sink |

| Material Available | Granite, Marble, Limestone, Travertine, Onyx, etc. |

| Color Available | White, Black, Yellow, Grey, Red, Brown, Beige, Green, Blue, ect. |

| Surface Available | Polished, Honed, Flamed, Natural, Bush-hammered, Mushroom, Pineapple, ect. |

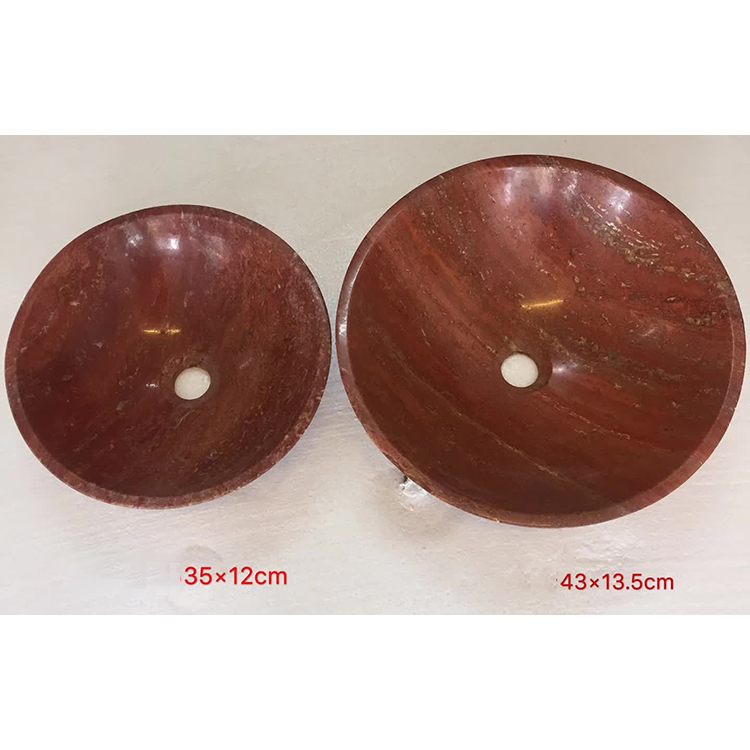

| Shape Available | Round, Oval, Square, Rectangular, Artistical, Based on Customer Request |

| Size | 420x420x14mm,525x400x14mm,600x457x110,810x457x95mm, Based on Customer Request |

| Popular Style | G684,G654,Mongolia Black, Emperador Marble, Portor Gold Marble, Nero Marquina Marble, Carrara White Marble, Shangxi Black Granite, Blue Limestone, Onyx Marble, ect. |

| Delivery Time | 10-15days after the order confirmed |

| Application | Bathroom, Kitchen, Bathtub, Outdoor Garden, Pool, ect. |

We offer a range of many models of stone sinks. The material of stone sinks include marble, granite, onyx, travertine stone, artificial quart, terrazzo stone and any other stone materials else. These stone basin supplied in white, black, grey, red, pink, beige, blue, etc.

Here we would like to share you the round red travertine stone sinks.

Travertine is an excellent natural stone that is both fashionable and affordable. Travertine sinks are less costly than marble sinks. It has a great aesthetic despite being significantly less expensive.

Travertine is regarded as a luxury material. And the material is extremely long-lasting. It is a fantastic choice since it absorbs water. Another enticing feature of travertine is that it is environmentally friendly. It is robust, durable, and magnificent as a naturally occurring substance.

Another key characteristic is versatility. Travertine is easier to cut when it is in the form of a tile. This makes it excellent for one-of-a-kind applications requiring odd forms.

Company Profile

Rising Source Group is as a direct manufacturer and supplier of natural marble, granite, onyx, agate, quartzite, travertine, slate, artificial stone, and other natural stone materials. Quarry, Factory, Sales, Designs and Installation are among the Group's departments. The Group was founded in 2002 and now owns five quarries in China. Our factory has a variety of automation equipment, such as cut blocks, slabs, tiles, waterjet, stairs, counter tops, table tops, columns, skirting, fountains, statues, mosaic tiles, and so on.

We have more stone material choices and one-stop solution & service for the marble and stone projects. Untill today, with the big factory, advanced machines , a better management style, and a professional manufacturing, design and installation staff. We have completed many large projects around the world, including government's buildings, hotels, shopping centers, villas, apartments, KTV and clubs, restaurants, hospitals, and schools, among others, and have built a good reputation. We make every effort to meet strict requirements for selection of materials, processing, packing and shipping to ensure that high-quality items reach securely at your location. We will always strive for your satisfaction.

Our Projects

Certifications:

Many of our stone products have been tested and certified by SGS to assure good quality products and best service.

Packing & Delivery

Pedestal sink: packing by fumigated strong wooden box package

Small sinks: 5 ply carton and poly bag for all basin with 2cm/6 side foam.

Why Choose Rising Source stone

What's your advantage?

Honest company at a reasonable price with competent export service.

How can you guarantee quality?

Before mass production, there is always a pre-production sample; Before shipment, there is always a final inspection.

Whether do you have a stable stone Raw materials supply?

A long term cooperation relationship is kept with eligible suppliers of raw materials, which ensures the high quality of our products from 1st step.

How is your quality control?

Our quality control steps include:

(1) Confirm everything with our client before moving to sourcing and production;

(2) check all the materials to ensure they are correct;

(3) Employ experienced workers and give them proper training;

(4) Inspection throughout the whole production process;

(5) Final inspection before loading.

Welcome to inquiry and visit our website for more product information

-

Vanity small wash basin round marble sink for b...

-

Custom natural carved freestanding marble stone...

-

Bathroom cabinet countertop oval hand wash blac...

-

Large bathroom walk-in tub black natural marble...

-

LED lighted translucent stone bathroom white ba...

-

Good price single small rectangular lavatory ba...

-

Bianco carrara natural white marble bathroom va...